Maximized Energy Efficiency Through Custom Solar Mounting Design

How Solar Panel Angle and Orientation Impact Energy Yield

The way solar panels are angled and positioned makes all the difference when it comes to how much energy they actually collect. Research from last year on solar mounting showed something pretty significant: panels set at their ideal tilt for a particular location can grab anywhere between 18 to 25 percent more power over the course of a year compared to just laying them flat in areas around the middle latitudes. Good installation companies know this stuff inside out. They design their mounting systems with three main factors in mind: where the sun is overhead based on the location's latitude, how its position changes throughout the seasons, and even small weather patterns specific to the area. All these considerations help ensure the panels soak up as much sunlight as possible throughout the day.

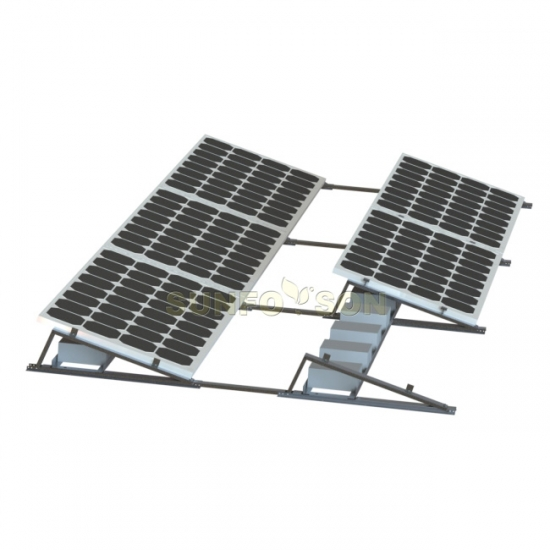

Adjustable Tilt and Azimuth: Optimizing Sun Exposure with Smart Racking

Advanced solar mounting systems now integrate hydraulic or motorized actuators that adjust panel tilt (15°–60° range) and azimuth orientation (±30°) seasonally. This dynamic alignment maintains near-perpendicular exposure to sunlight, increasing daily energy yield by 8–12% compared to fixed-tilt systems. Predictive weather modeling further enhances performance by preemptively adjusting angles during cloudy periods.

Case Study: 27% Efficiency Gain in a Commercial Denver Rooftop Installation

In Denver, a 340kW solar setup managed to get about 27% more energy per year thanks to some special mounting solutions. The engineers behind it went with a base angle of around 28 degrees to catch those winter rays better, included brackets that keep snow from piling up (they clear about 15 inches), and spaced everything out in a way that stands up to strong winds. What did this customization do? Well, the system actually got around 8.2 peak sun hours each day. That's roughly 1.3 hours extra compared to what other similar installations without these tweaks managed. So when looking at actual performance numbers, it becomes pretty clear how much difference thoughtful design can make in real world conditions.

AI-Driven Modeling for Site-Specific Solar Mounting Configurations

Machine learning algorithms analyze up to 38 variables—including roof obstructions, shading from adjacent buildings, and topography—to generate optimal mounting layouts. One proprietary AI model reduced design time by 65% while achieving 97.4% accuracy in simulated energy yield, far surpassing traditional manual methods.

Integrating Solar Access Analysis into Customized Racking System Design

Custom racking integrates drone-based LiDAR scans with 3D irradiance modeling to eliminate inter-row shading. In a Boston mixed-use development, this approach enabled 18% higher panel density while maintaining 90% annual solar access—a crucial advantage in Northeastern climates with limited peak sun availability.

Superior Durability of Custom Solar Mounting in Harsh Environments

High failure rates of generic mounts in extreme wind and snow conditions

Generic solar mounting systems fail frequently under environmental stress, with 40% of photovoltaic damage during extreme weather events attributed to inadequate fasteners (Solar Energy World 2023). Standard clamps often cannot withstand winds over 90 mph, and pre-set snow load tolerances frequently misalign with regional climate patterns.

Structural engineering principles: Meeting wind, snow, and seismic load requirements

Custom solar mounting applies aerospace-grade structural analysis to address site-specific forces. Engineers use localized wind pressure coefficients, snow density data, and seismic acceleration maps to design racking systems that exceed International Building Code standards by 25–40% safety margins.

Case Study: Coastal Florida solar array surviving a Category 3 hurricane

A Miami-area solar array withstood 115 mph winds from a Category 3 hurricane thanks to dual-axis torque tubes and helical ground anchors. Post-storm inspections showed zero panel loss, contrasting sharply with 62% failure rates in neighboring arrays using generic mounts.

Corrosion-resistant materials for long-term performance in coastal areas

Marine-grade aluminum alloys with ceramer coatings demonstrated 98% corrosion resistance after 15 years of salt spray testing. Electropolished stainless steel hardware prevents galvanic degradation, ensuring structural integrity even in environments with year-round humidity above 90%.

Selecting solar mounting systems based on environmental exposure and material durability

Leading developers now use climate-indexed material selection matrices, pairing anodized aluminum for arid zones with zinc-nickel plated steel in temperate regions. This strategy reduces replacement needs by 70% compared to one-size-fits-all solutions.

Design Flexibility for Diverse Roof Types and Installation Challenges

Installation challenges on irregular, historic, or mixed-material rooftops

Most standard mounting systems just don't cut it when dealing with complicated roof setups. According to research from NREL in 2023, about three out of four installation delays happen because the racking doesn't fit properly. Old buildings pose special challenges since they need mounts that won't damage their original features. Then there are those tricky composite roofs covered in everything from asphalt shingles to metal flashing and clay tiles, which often call for mixed approach solutions. Several big problems keep coming up during installations. First, spreading the weight evenly across older structures that are already over two decades old can be risky business. Second, meeting preservation requirements varies greatly depending on location, with different rules in place throughout nearly half the country. And finally, materials expand at different rates when heated, leading to all sorts of alignment issues down the road if not properly addressed during installation.

Industry research shows custom adapters reduce structural stress by 30% compared to off-the-shelf alternatives (SoEasyRobot 2023).

Customizing solar mounting systems for structural compatibility and safety

When dealing with roofs that have unusual shapes and angles, site specific engineering makes all the difference in creating structures that can handle their actual loads. Take a commercial building in Seattle as an example they needed special brackets to adjust for roof slopes ranging from just 7 degrees up to nearly 30 degrees. They used aluminum clamps that work equally well with metal seams and PVC membranes, plus added reinforcement against wind speeds reaching 130 miles per hour. This tailored approach saved them around fifteen thousand dollars that would have gone toward fixing problems later on, not to mention keeping those original roof warranties intact which is always a big plus for property managers looking to avoid headaches down the road.

Modular, rail-free mounting systems for faster, non-invasive rooftop deployment

Rail-free technologies reduce installation labor by 40% through simplified component integration:

| Feature | Traditional Systems | Rail-Free Systems |

|---|---|---|

| Components per panel | 12–18 | 4–6 |

| Roof penetrations | 8–10 per panel | 0–2 per panel |

| Weight distribution | Concentrated | Even dispersion |

These systems use interlocking polymer bases that adapt to roof irregularities while meeting NEC 2017 wind uplift standards.

Expanded Application Versatility with Specialty Solar Mounting Solutions

Growing demand for solar in non-traditional spaces: carports, canopies, and agrivoltaics

The way we mount solar panels isn't just limited to rooftops anymore. According to research from the National Renewable Energy Lab in 2023, these multi-use structures such as solar carports actually boost how productive urban spaces can be by about double what regular parking lots manage. Many colleges and city governments have started installing these carport systems across their campuses and public lots. Each parking spot typically produces somewhere between 300 to 500 kilowatt hours every year, plus it keeps vehicles protected from rain and sun. There's also this interesting trend called agrivoltaics where farmers put solar panels on poles above their fields. Tests at the University of Arizona showed crops still grew pretty well at around 85% of normal levels even with the panels overhead, all while the land was producing clean electricity too.

Ground-mounted and canopy solar racking for dual-use land optimization

Advanced ground-mounted racking supports vertical integration with agriculture and public infrastructure. Dual-axis tracking systems optimize light distribution for crops while boosting energy yields by 18–22% (Fraunhofer ISE 2023). Canopy-style racking in urban areas provides 70–90% shade coverage without sacrificing output, enabled by transparent photovoltaic glass integration.

Case Study: Solar carport installation at UC San Diego parking structure

The 6.1 megawatt solar carport at UC San Diego is pretty impressive when it comes to scaling up specialty mounting solutions. What's really cool about it? No rails needed! The installation spans around 15,000 parking spots spread across five different buildings, all while keeping things accessible according to ADA requirements. Even though the coast gets pretty windy sometimes (upwards of 45 mph gusts), this setup has held strong during three consecutive El Niño weather events. On average, the system generates about 7.8 million kilowatt hours each year, which covers roughly a quarter of the campus's power needs during daylight hours. Not bad for something that fits right into existing parking lots!

Agrivoltaics: Integrating elevated ground mount solar with agricultural land use

Three-dimensional mounting configurations enable synergistic land use. A 2023 NREL-agribusiness partnership demonstrated:

| Installation Type | Crop Yield | Energy Output | Land Use Efficiency |

|---|---|---|---|

| Traditional Farming | 100% | 0% | 1x |

| Standard Solar Farm | 0% | 100% | 1x |

| Agrivoltaic Array | 83% | 87% | 1.7x |

Elevated racking (7–10 ft clearance) allows full-sized farming equipment to operate beneath panels, reducing irrigation needs through partial shading.

Urban land efficiency through carport solar racking systems

In dense cities, solar carport racking maximizes vertical energy density. A 2024 Urban Solar Initiative report showed retrofitted parking structures achieve 0.81 MW/acre, more than double the 0.33 MW/acre of conventional ground mounts. Modular designs support phased deployment, with top installations reaching 1.2 MW per city block without reducing parking capacity.

Long-Term Cost Savings and ROI of Tailored Solar Mounting Systems

Hidden costs of retrofitting standard solar mounts post-installation

Generic mounting systems often require costly post-installation modifications, averaging $18–$32 per watt in retrofit expenses (2024 industry analysis). These unplanned costs arise from structural reinforcement, disassembly/reassembly labor, and production losses during downtime—all avoidable with upfront customization.

Balancing upfront investment with lifecycle savings in custom solar mounting

Although custom mounting requires a 10–15% higher initial investment, it reduces operational expenses by 22–35% over 25 years. Precision engineering minimizes maintenance needs, a critical benefit given that O&M accounts for 75% of lifetime solar costs (Solar Energy Industries Association 2023).

Case Study: 35% O&M cost reduction at a Minnesota industrial warehouse

A 1.2MW Minneapolis rooftop system achieved $240,000 in annual savings via custom mounting featuring pre-assembled clamp systems, integrated snow load sensors for automated tilt adjustment, and corrosion-resistant aluminum components. These innovations supported 98.6% uptime during harsh winters and delivered full ROI within 6.3 years.

Conducting lifecycle cost analysis for specialty solar mounting solutions

Forward-thinking developers evaluate mounting options using a 30-year cost framework:

| Factor | Standard Mounts | Custom Mounts |

|---|---|---|

| Installation labor | $12,500/MW | $9,800/MW |

| Annual maintenance | $4,200/MW | $2,750/MW |

| Structural upgrades | $18,000/MW | $0/MW |

| Energy loss prevention | 3.8% | 0.9% |

This comprehensive analysis confirms that custom solar mounting delivers 18–27% better lifetime value across diverse climates and applications.

FAQ Section

What are the benefits of adjustable solar panel angles?

Adjustable angles increase daily energy yield by optimizing exposure to sunlight, allowing systems to adapt to seasonal changes for maximum efficiency.

How do custom adapters reduce structural stress?

Custom adapters reduce structural stress by allowing tailored fit to unique roof shapes and materials, effectively distributing load and preventing damage.

Why are corrosion-resistant materials important in coastal solar installations?

Corrosion-resistant materials prevent degradation due to high humidity and salt exposure, ensuring long-term performance and reduced maintenance costs.

What is agrivoltaics?

Agrivoltaics involves integrating solar panels with agriculture, allowing synergistic land use where crops and solar power generation coexist.

How does custom solar mounting affect ROI?

Custom mounting systems require a higher upfront investment but reduce operational expenses significantly, leading to higher long-term ROI.

Table of Contents

-

Maximized Energy Efficiency Through Custom Solar Mounting Design

- How Solar Panel Angle and Orientation Impact Energy Yield

- Adjustable Tilt and Azimuth: Optimizing Sun Exposure with Smart Racking

- Case Study: 27% Efficiency Gain in a Commercial Denver Rooftop Installation

- AI-Driven Modeling for Site-Specific Solar Mounting Configurations

- Integrating Solar Access Analysis into Customized Racking System Design

-

Superior Durability of Custom Solar Mounting in Harsh Environments

- High failure rates of generic mounts in extreme wind and snow conditions

- Structural engineering principles: Meeting wind, snow, and seismic load requirements

- Case Study: Coastal Florida solar array surviving a Category 3 hurricane

- Corrosion-resistant materials for long-term performance in coastal areas

- Selecting solar mounting systems based on environmental exposure and material durability

- Design Flexibility for Diverse Roof Types and Installation Challenges

-

Expanded Application Versatility with Specialty Solar Mounting Solutions

- Growing demand for solar in non-traditional spaces: carports, canopies, and agrivoltaics

- Ground-mounted and canopy solar racking for dual-use land optimization

- Case Study: Solar carport installation at UC San Diego parking structure

- Agrivoltaics: Integrating elevated ground mount solar with agricultural land use

- Urban land efficiency through carport solar racking systems

- Long-Term Cost Savings and ROI of Tailored Solar Mounting Systems

- FAQ Section