Understanding Solar Carport Basics and System Types

What Is a Solar Carport and How Does It Work?

Solar carports serve two main functions at once they protect cars from weather damage while also producing electricity thanks to those solar panels on top. What makes them different from regular carports? Well, instead of just sitting there doing nothing, these installations actually capture sunlight and turn it into real power. Most homes see their monthly bills drop by around half when using one of these setups according to industry reports from last year. The electricity produced has several uses too it powers nearby structures, charges EV batteries, and even sends extra juice back to local utility companies under certain programs. These days we're seeing panels with efficiencies between 18 and 22 percent, which means manufacturers have made some serious improvements over time. And don't worry about maintenance issues either since quality models usually last about 25 years before needing replacement parts.

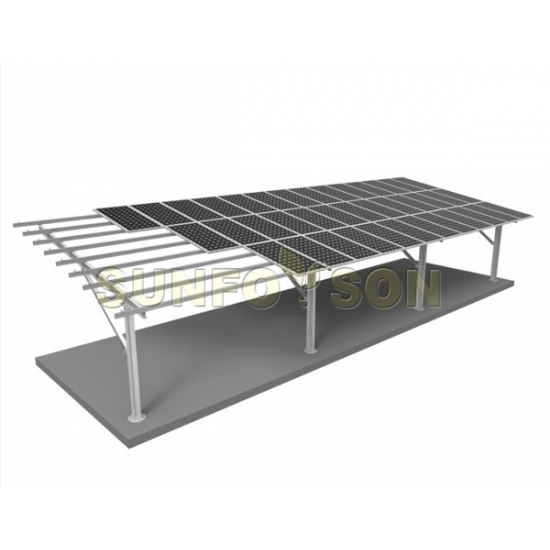

Common Types of Solar Carports: Residential, Cantilever, and Ground-Row Systems

Three primary configurations dominate the market:

- Residential: Compact designs for 1–3 vehicles (5–25 kW capacity)

- Cantilever: Single-column structures that maximize parking space utilization

- Ground-Row: Multi-row layouts ideal for large commercial parking lots (40+ kW)

Cantilever systems use 40% less steel than conventional frames but may require deeper foundations in high-wind areas. Ground-row installations offer higher energy density, with some commercial setups generating over 1.2 MWh annually per parking space.

Material Choices for Durable and Efficient Structures: Aluminum, Steel, and More

| Material | Cost (per sq.ft) | Weight (lbs/sq.ft) | Corrosion Resistance | Best For |

|---|---|---|---|---|

| Aluminum | $16–$22 | 8–12 | High | Coastal regions |

| Galvanized Steel | $12–$18 | 15–20 | Moderate | Budget projects |

| Stainless Steel | $24–$30 | 18–25 | Very High | High-snow areas |

Aluminum is used in 68% of residential installations due to its favorable strength-to-weight ratio. Galvanized steel remains the preferred choice for large-scale projects requiring load capacities above 50 tons (National Renewable Energy Lab, 2022).

Assessing Site Suitability and Structural Requirements

Evaluating Solar Exposure, Shading, and Optimal Orientation

Solar carports require 800-1200 kWh/square meter/year of solar radiation to operate effectively (NREL 2023). Use tools such as Solar Pathfinder to evaluate the shading of nearby trees or buildings - only 20% shading coverage can reduce yield by 34%. In the northern hemisphere, the structure should be oriented within 15 ° towards the south to maximize the annual irradiance capture rate.

Space Planning: Clearance, Vehicle Access, and Layout Efficiency

Ensure a vertical clearance of at least 8 feet to accommodate taller vehicles and allow for panel tilt adjustment. For multi row systems, the space is supported every 12-16 feet to maintain structural integrity while optimizing light penetration. The 2-3 foot spacing between rows minimizes mutual obstruction and improves airflow for snow removal and wind resistance.

Foundation and Soil Considerations for Long-Term Stability

Soil must support loads exceeding 3,000 PSF, especially in areas with heavy snow (30+ lb/ft²) or high winds (90 mph). Steel-reinforced concrete piers or helical anchors are recommended for clay-rich soils, reducing settlement risk by 85% compared to surface footings (ASTM International 2023). In coastal zones, galvanized materials help resist salt-induced corrosion.

Engineering for Resilience: Wind, Snow Loads, and Regional Compliance

Calculating Environmental Loads by Geographic Region

When designing structures, engineers need to consider local weather conditions through established guidelines. For coastal areas, wind speeds can reach as high as 170 miles per hour, which puts around 50 pounds of upward force on each panel. Up in mountainous terrain, designers have to factor in snow loads exceeding 70 pounds per square foot. Cities bring their own set of problems too. The way buildings are positioned next to each other creates what's called wind tunnel effects, and this can boost pressure levels by anywhere between 15 and 20 percent when compared to open spaces outside urban centers.

Balancing Lightweight Design with Structural Durability

Material selection impacts both performance and longevity. Aluminum alloys (6061-T6 or 6063-T5) reduce weight by 40% versus steel without sacrificing strength, though they need protective coatings in salty coastal air. Galvanized steel provides superior load-bearing capability in snowy climates, with corrosion-resistant treatments extending service life by 20–25 years.

Ensuring Code Compliance and Safety Standards

Solar carport structures need to meet ASCE 7-22 guidelines regarding environmental stresses as well as follow International Building Code requirements. According to research published last year, around two thirds of structural problems actually come down to poor installation of wind uplift fasteners or old fashioned methods for calculating snow loads. Getting third party engineers to check these systems ensures they're up to spec when it comes to fire safety distances, earthquake resistance, and proper exits during emergencies. This kind of verification cuts down potential legal issues significantly in areas where regulations are strictly enforced, though exact numbers vary depending on location specifics.

Navigating Permits, Regulations, and Community Approvals

Meeting Zoning Laws, AHJ Requirements, and Fire Safety Codes (e.g., NEC 690.12)

Any project needs to fit within local zoning laws, what the AHJ says is okay, and fire safety standards too. Take NEC 690.12 for instance, it actually demands those quick shut down systems for solar panels. Now here's something interesting about different places: setback requirements, how tall buildings can be, and whether structures need special certification all change depending on where you are. And don't forget about fire codes either. These often specify how far apart panels should sit and where conduits need to go, mainly because they want to prevent dangerous electrical arcs. Getting regulatory folks involved right at the start, ideally while blueprints are still being drawn, saves everyone headaches later on. Some research found that when teams talk to officials early, they end up doing about 40 percent less rewriting of plans. Permitting offices regularly point out that checking soil conditions and calculating wind loads becomes really critical in areas prone to severe weather events.

Securing HOA Approval and Addressing Neighborhood Restrictions

Homeowner associations (HOAs) commonly impose aesthetic or operational constraints, including:

- Height restrictions matching existing structures

- Approved color schemes for framing

- Noise limits for inverters or cooling units

Over 60% of residential solar carport projects in planned communities receive at least one HOA design modification request. Sharing detailed renderings and projected energy yields with architectural review boards can accelerate approvals.

Case Study: Reducing Delays in Municipal Permitting Processes

In 2022, a commercial project somewhere in the Midwest managed to cut down on permitting delays quite dramatically, around half actually, thanks to what they called a phased approval strategy. The builders got clever about it too - they sent over just the foundation plans first instead of waiting until all the electrical blueprints were ready. This let them get some permits approved right away while they still worked out details about the solar panels. When paired with those new digital tracking systems everyone's talking about these days, the whole review process went from taking nearly two months down to just six weeks flat. Pretty impressive stuff according to the folks who wrote up the Municipal Efficiency Report last year, which specifically highlighted how well this works for bigger renewable energy projects across the country.

Integrating EV Charging and Financial Planning for Solar Carports

Solar carports uniquely integrate renewable generation with EV charging infrastructure, combining energy production and transportation electrification. With 52% of U.S. businesses planning to install EV chargers by 2025 (DOE 2023), these systems are becoming critical for sustainable fleet and facility management.

Solar Carports as EV Charging Hubs: Electrical Integration and Inverter Selection

Effective integration requires smart inverters that manage power flow between solar panels, battery storage, and Level 2 or DC fast chargers. Centralized inverters work well for large arrays (50kW+), while microinverters provide module-level optimization in partially shaded environments. Key considerations include:

- Coordinating peak demand to avoid grid overload during simultaneous charging

- Supporting bi-directional vehicle-to-grid (V2G) capabilities

- Ensuring compliance with NEC 705 for safe utility interconnection

Cost Analysis and ROI: Upfront Investment vs. Energy Savings and Incentives

Commercial solar carports integrated with electric vehicles typically achieve returns within 7-12 years through the following methods:

- Federal Investment Tax Credit (ITC), covering 30-50% of installation costs

- Save an average of $740 in demand costs per month through peak shaving (Ponemon 2023)

- California's $1 billion charging readiness plan and other state incentives

Pairing battery storage with Time-of-Use arbitrage strategies can increase annual ROI by 18%, particularly under commercial utility rate structures.