Understanding BIPV and the Role of Solar Mounting Systems

What Is BIPV and How It Differs from Traditional Solar Installations

Building Integrated Photovoltaics, or BIPV for short, basically take the place of regular building materials like roofs, walls, and even windows by incorporating solar power generating components right into them. Traditional solar setups just stick panels on top of buildings, but BIPV does something different. These systems actually perform two jobs at once they provide structural support while also making electricity. Take photovoltaic glass used in skylights for example. It keeps the building insulated against temperature changes, protects from rain and wind, and still manages to produce usable power. According to research published in Renewable Energy in 2025, buildings with BIPV installed showed about 53 percent better thermal performance compared to standard roofs made with asphalt shingles or metal sheets. This kind of efficiency makes a real difference in long term energy costs for property owners.

Key Applications of BIPV in Modern Residential and Commercial Buildings

- Residential: Solar tiles that mimic slate or terra-cotta roofing

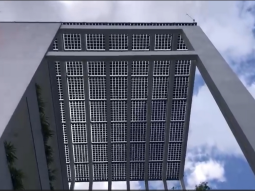

- Commercial: Semi-transparent BIPV curtain walls in high-rises

- Industrial: Structural solar canopies for parking lots

These applications reduce grid dependence while meeting aesthetic requirements. In colder climates, BIPV roofs also minimize snow accumulation through integrated heating elements a feature not typically found in standard rooftop arrays.

Integration of Solar Tiles, Shingles, and Other Building-Integrated Mounting Platforms

Advanced solar mounting platforms must address material compatibility, thermal expansion, and weight distribution. The following table outlines key differences:

| Design Factor | BIPV Requirement | Traditional Solar Requirement |

|---|---|---|

| Load Capacity | Structural replacement (>45 lb/ft²) | Add-on support (15-25 lb/ft²) |

| Weatherproofing | Integral to building envelope | Separate waterproofing membrane |

| Aesthetic Flexibility | 12+ color/texture options | Standard dark-blue panels |

This integration requires early collaboration between architects and solar engineers to ensure compliance with building codes and optimize energy output.

Structural and Environmental Challenges in BIPV Solar Mounting

BIPV solar mounting systems face unique structural and environmental demands that require precise engineering for safety, performance, and regulatory adherence.

Roof Load Bearing Capacity and Building Code Compliance

The average rooftop solar system adds 5–7 pounds per square foot (NREL 2023), making structural assessments essential—especially for older buildings. Engineers must evaluate roof frameworks and reinforce supports if needed to meet International Building Code (IBC) standards. Without accurate load calculations, 23% of BIPV projects may require costly post-installation modifications.

Wind, Snow, and Climate Specific Load Considerations

When installing systems in mountainous areas, they have to handle snow loads well over 150 pounds per square foot. Coastal setups face different problems though, needing protection against strong winds during hurricanes. A recent study from 2024 looked at buildings with solar panels mounted on walls in Sweden and discovered something interesting. These systems actually produced about 18 percent more energy in winter months because sunlight bounced off the surrounding snow. This kind of finding shows that good mounting designs aren't just about surviving harsh conditions but can actually make those same conditions work better for us.

Thermal Bridge Prevention and Energy Efficiency in Mounting Design

Uninsulated metal brackets can cause 12–15% heat loss through thermal bridging. Aerogel-insulated clamps now reduce this by up to 90% compared to traditional aluminum mounts, maintaining structural integrity while improving building energy efficiency, as confirmed by third-party testing.

Balancing Aesthetic Integration with Structural Safety Requirements

Semi-transparent solar facades conceal load-bearing components within curtain wall mullions, achieving near invisible integration. However, this visual benefit requires 40% thicker aluminum substructures to maintain wind resistance an important trade off between architectural intent and engineering necessity.

Design and Installation Best Practices for Reliable BIPV Mounting

Best Practices for Secure and Weatherproof Solar Panel Mounting

Reliable BIPV mounting relies on corrosion-resistant aluminum brackets, stainless steel fasteners, and butyl rubber seals to prevent water ingress. Dual-purpose clamps that act as thermal breaks help reduce condensation risks, according to a 2024 review of modular BIPV integration. Essential practices include:

- Optimal tilt angles (15–35° depending on latitude)

- Expansion joints to manage thermal movement

- Annual inspections of sealants and torque settings (12–15 Nm for rail connections)

These measures support long-term durability and alignment with international standards like IEC 61215.

Precision vs. Speed: Trade Offs in Modular BIPV System Installation

Modular systems assembled at factories save around 30% in on-site labor costs, but they require extremely precise alignment down to fractions of a millimeter. For big projects, robotic equipment helps maintain consistency across installations. Still, workers often have to make hand adjustments when dealing with tricky roof connections where machines just cant reach. When things get misaligned, efficiency drops between 5 and 9 percent because of shadowing issues or structural stress problems. That makes finding the sweet spot between fast installation and exact measurements absolutely critical for successful deployments.

Quality Control Measures During BIPV Mounting Processes

A three-stage verification process ensures reliability:

- Substrate flatness checks (≤3 mm variance)

- Smart torque wrenches with real-time data logging

- Post-installation pull tests (≥ 50 kgf retention force)

Thermal imaging detects poorly connected components, while strain gauges monitor stress points. Together, these controls reduce warranty claims by 40% in commercial deployments.

Case Study: Integrated Sunshade and Carport BIPV System in a Net Zero Office Building

A 12,000 m² corporate campus achieved 95% energy self-sufficiency using cantilevered solar sunshades at a 22° tilt and suspended carport arrays. By eliminating separate support structures, the project reduced material costs by 30%. Rail-mounted panels allow individual replacements without dismantling entire sections, showcasing scalable maintenance solutions for complex BIPV designs.

Maintenance, Accessibility, and Long Term Performance of Mounted BIPV Systems

Overcoming Maintenance Challenges in Fully Integrated Solar Mounting Setups

Building-integrated photovoltaic (BIPV) systems need special care because they're built right into the walls and roofs of structures. According to a study in Solar Energy Materials & Solar Cells journal, these integrated installations actually cut down on how often technicians need to perform maintenance checks by about 22%. But when service does become necessary, it tends to take around 40% more time since workers have limited access points. The real headaches come from cleaning all those complicated shapes and trying to reach electrical parts that are tucked away behind other materials. For this reason, many facilities now rely on predictive maintenance techniques such as infrared scans which can spot potential hotspots developing within the sealed solar panels long before anyone notices any drop in energy output.

Designing for Serviceability Without Compromising Building Integrity

Smart design these days often includes removable panels and modular parts that make maintenance much easier. According to industry data, buildings with these features tend to save around 33% on operating expenses long term without compromising the watertight integrity. The latest Building Integrated Photovoltaics Maintenance Report from 2024 shows something pretty impressive too. With those new tool free fasteners, replacing modules takes just 90 minutes now instead of taking 8 hours or more with older systems. When planning for regular access points, designers need to keep thermal continuity intact and go for UV resistant gasket materials. These small but important details really matter for buildings that require frequent servicing.

Durability and Weather Resistance of Solar Mounting Solutions Over Time

Accelerated aging tests show high performance BIPV mounting systems retain 92% structural integrity after 30 years in coastal environments when using marine-grade aluminum and embedded drainage. Key durability factors include:

- Matching coefficients of thermal expansion between hardware and substrates

- Coatings rated for 25+ years of UV exposure

- Less than 0.5% permanent deformation under extreme snow loads at -40°C (Solar Tech Institute 2023)

Retrofitting and Upgradability of Existing BIPV Mounting Infrastructure

Many BIPV systems installed between 2005 and 2015 now require upgrades, with 68% needing reinforcement to support heavier modern panels (NREL 2024). Effective retrofit strategies include:

- Interoperable adapter brackets for new PV laminates

- Distributed microinverters to bypass outdated central wiring

- Load-distribution plates that strengthen original mounting points

A 2023 case study showed that replacing older solar spandrels with lightweight PERC modules saved 40% compared to full system reconstruction.

FAQs

What is BIPV?

Building Integrated Photovoltaics (BIPV) refers to solar panels integrated directly into building materials such as roofs, walls, or windows, serving both energy generating and structural purposes.

How does BIPV differ from traditional solar panels?

BIPV replaces building materials, performing dual functions, while traditional solar panels are added onto existing structures.

What are the benefits of BIPV?

BIPV enhances aesthetic appeal, improves energy efficiency, and can reduce long-term energy costs.

What maintenance challenges does BIPV face?

BIPV systems require less frequent maintenance but can take longer to service due to integrated and complex designs.

Can existing buildings be retrofitted with BIPV?

Yes, many existing BIPV systems can be upgraded to support modern panels and technologies.