Tin Roof Mounting Bracket

-

Item No.: SFS-PR-01

Payment: L/C T/T

Product Origin:Fujian,China

Color: Natural or Customized

Shipping Port: Xiamen

Lead Time: 20 days

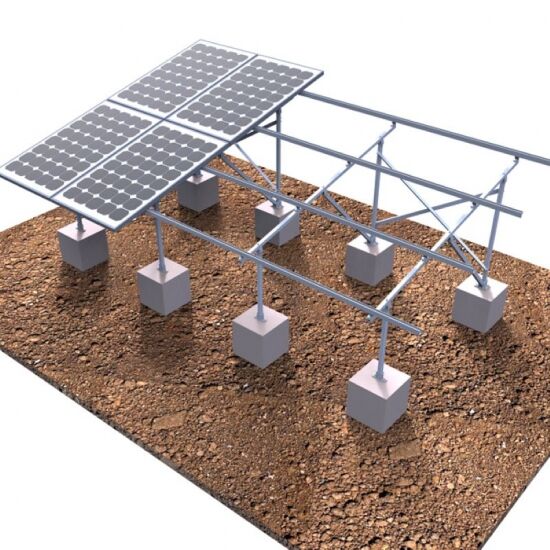

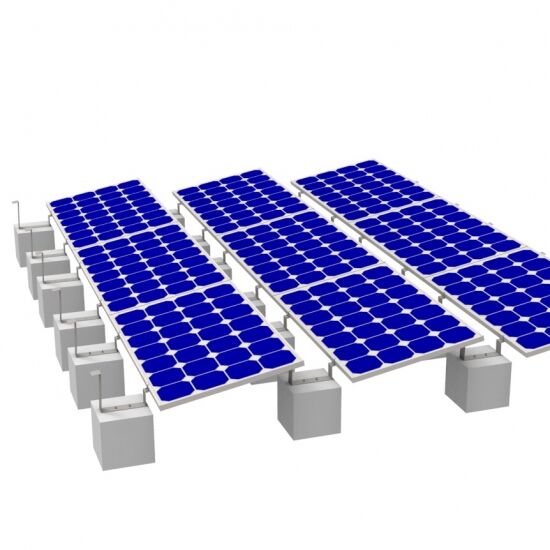

- Overview

- Recommended Products

- Easy Installation:

The innovative Sunforson solar rail and N- modules have greatly simplified the installation of PV modules. The System can be installed with a single Hexagon Key and standard tool kit. The Solar Roof system is aided by a very high level of preassembly. The N module and unique rail extension method greatly reduce installation time. - Great Flexibility:

With the Sunforson Solar Roof, framed photovoltaic modules can be easily mounted on pitched roofs. The Solar Roof system has mounting accessories designed for application on almost every roof cladding available with unique rail. - High Accuracy:

Without the need of onsite cutting, the use of our unique rail extending allows the system to be installed with millimeter accuracy. - Excellent Adaptability:

The height adjustment of the rails from Sunforson allows a level PV array to be established, no matter how uneven the roof

is.Engineered to high standard Sunforson solar roof is made to the highest standard, safe and strong design to comply with BS6399-2-1997 - Maximum Lifespan:

All components are made of quality extruded aluminum and stainless steel. The high corrosion resistance guarantees the maximum possible lifespan and is also completely recyclable. - Guaranteed Durability: Maximum Lifespan:

Sunforson provides a guarantee of 10 years on the durability of all components used.

With a variety of different tin roof brackets, SunRack tin roof mounting system can meet trapezoid/corrugated metal roof and standing seam roof demand with or without penetrating the roofs. Sunforson has an excellent engineering team and quality management system to provide the perfect service.

| Installation site | Tin roof |

Application |

Framed solar panel for any size |

| Material | Aluminum, stainless steel |

| Wind load | up to 60m / s |

| Snow load | up to 1.4KN / m2 |

Inclination |

0 degree (the same angle as roof) |

Panel direction |

vertical or landscape |

Design Standards |

BS EN 1991-1-4:2005 / ASCE 7 / DPT 1311 |

Warranty |

10 years quality warranty and 25 years design life |

Products Strengths

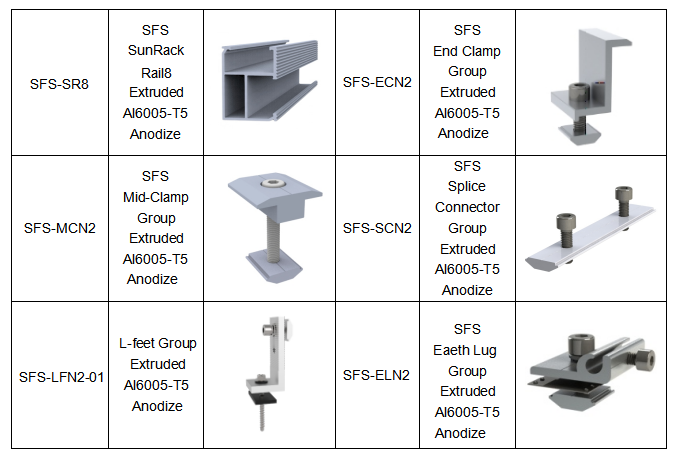

Overview of system components

Installation Guide

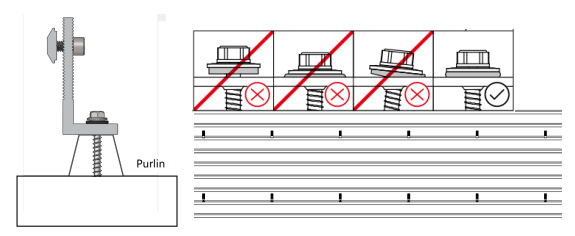

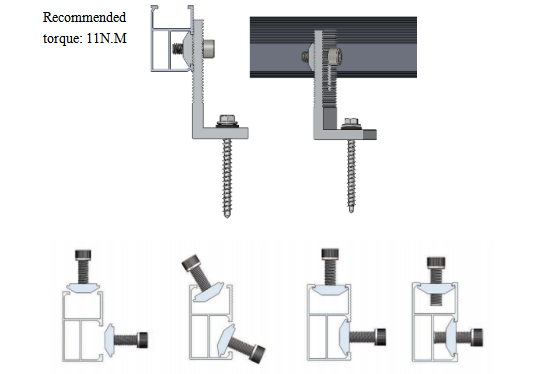

1) Install L Feet

All L-feet groups shall be fixed on the purlin according to the dimensions of the above layout drawing and must be fixed to the purlin.

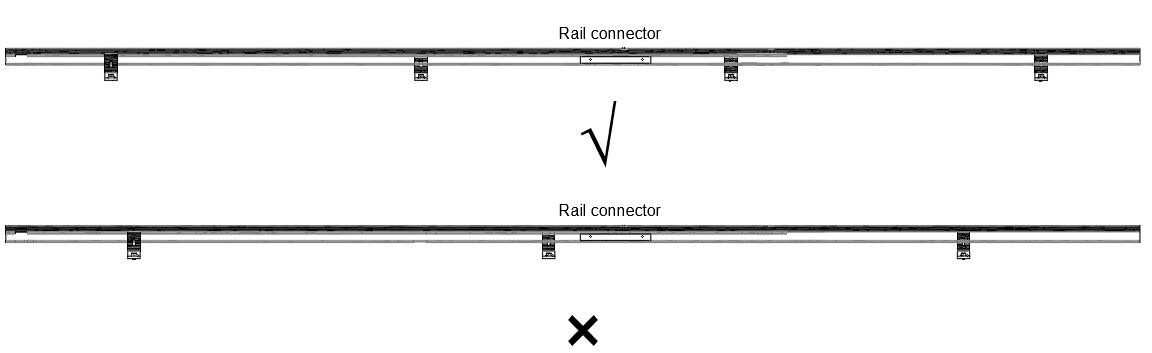

2) Rail installation

As reference,Install rail with N Nut-module. (Note :Each rail must have 2 support point.)

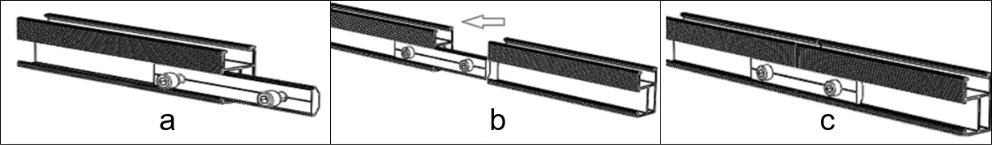

3) Rail connector installation

To connect multiple rails together, slide the splices on the rear side of the pre-assembled rails halfway to the side. Fasten the first M8 Allen bolt firmly using the Allen key. Now slide the next rail segment into the splice. Tighten the second M8 Allen bolt using the Allen key. The connection is finished. An expansion gap at the rail joints is recommended. For this purpose, leave a gap about the same width as a 2~3mm between the rail joints and then loosely tighten the M8 allen bolt

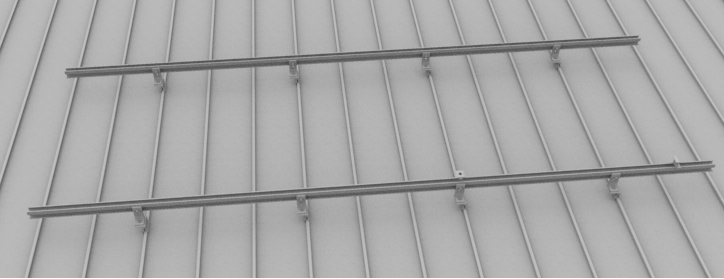

Install results are shown below:

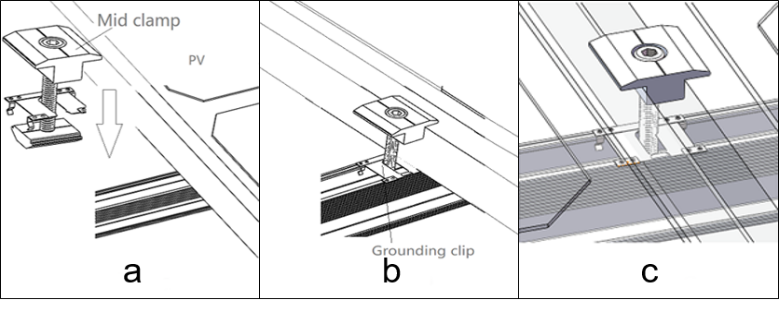

4) Solar clamp installation

As follow picture show to install Mid clamp

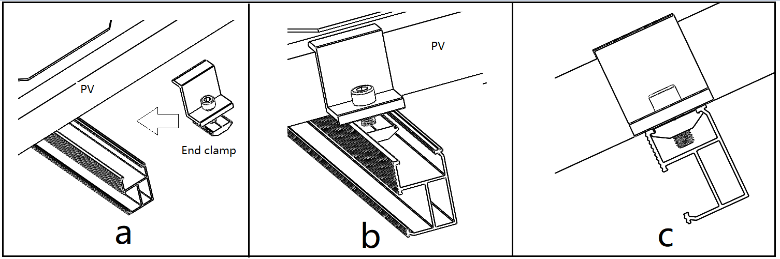

As follow picture show to install end clamp

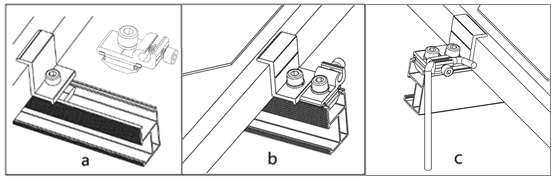

5) Earth lug installation

Install the Earth Lug Group, then use conductive materials such as copper wire to place it on the Earth Lug Group, and place the other end on the ground for grounding treatment. When installing the grounding gasket, you can choose to install it at either end of the most side end, but it is recommended that you install it at a position more convenient for wiring.

Sunforson is a professional manufacturer of solar mounting systems, headquartered in China with branch companies in Thailand, Vietnam, and Nigeria. We specialize in the design and production of SunRack solar mounting solutions for global solar projects. With stable production capacity, strict quality control, and localized support, we provide reliable products, on-time delivery, and project-oriented service to customers worldwide.

Production Workshop

Standardized manufacturing processes ensure stable quality and efficient production.

Advanced Equipment

Well-equipped production lines for aluminum and stainless steel solar mounting components.

Warehouse & Packaging

Organized warehouse and professional packaging guarantee safe and efficient shipment.

Export Loading

Finished products prepared and loaded for global delivery.

FAQ– Frequently Asked Questions

Q1: What types of solar panels are compatible with this mounting system?

A: The system is compatible with most framed solar modules on the market and supports different panel sizes and power ratings.

Q2: What is the warranty period for the mounting system?

A: The standard warranty period is 10 years, with a design service life of up to 25 years.

Q3: Can the mounting system be customized for specific projects?

A: Yes. Customization is available based on project layout, site conditions, wind load, and snow load requirements.

Q4: Is the mounting system suitable for harsh environments?

A: Yes. The system is designed to withstand strong wind, heavy snow, and corrosive environments using anodized aluminum and galvanized steel.

Q5: Are all mounting accessories included in the package?

A: Yes. Rails, clamps, fasteners, and necessary accessories are supplied as a complete system.

Customer Cases

Rooftop Solar Project – Indonesia

Location: Indonesia

Project Scale: 1.45MW rooftop solar system

Application: Industrial factory rooftop

Performance & Results:

The mounting system was installed efficiently with minimal roof impact. After commissioning, the system has remained stable under strong wind and seasonal snow conditions, delivering reliable long-term performance.