Flat Roof Solar Mounting System Installation

-

Item No.:

SFS-FR-01 -

payment:

L/C, T/T -

product origin:

Fujian,China -

color:

Natural or Customized - Tilt Degree: Customized

-

shipping port:

Xiamen -

lead time:15

days

- Overview

- FAQ

- Recommended Products

- Pre-installation planning: On-site survey of roof conditions, load-bearing assessment, and layout design.

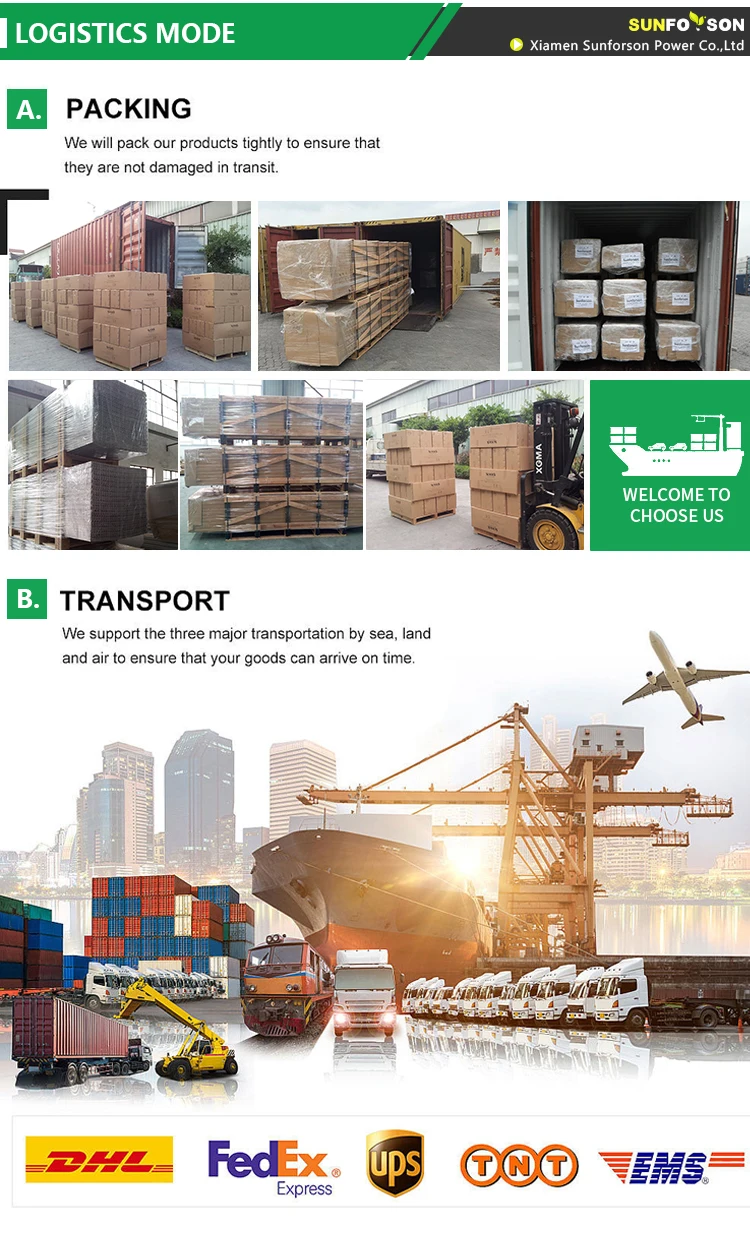

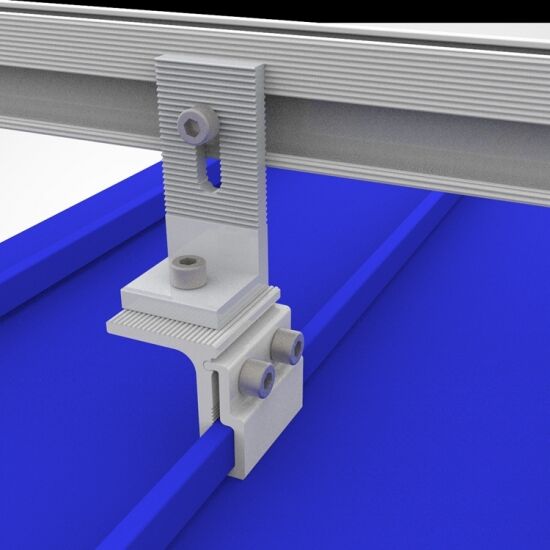

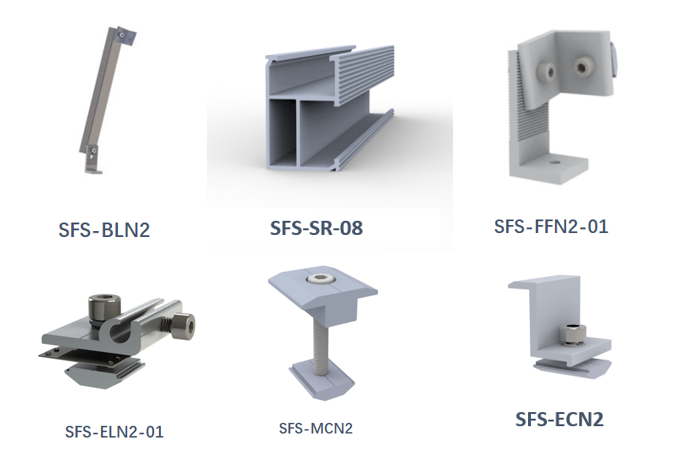

- Material preparation: Delivery of pre-assembled components, concrete ballast blocks, and installation tools.

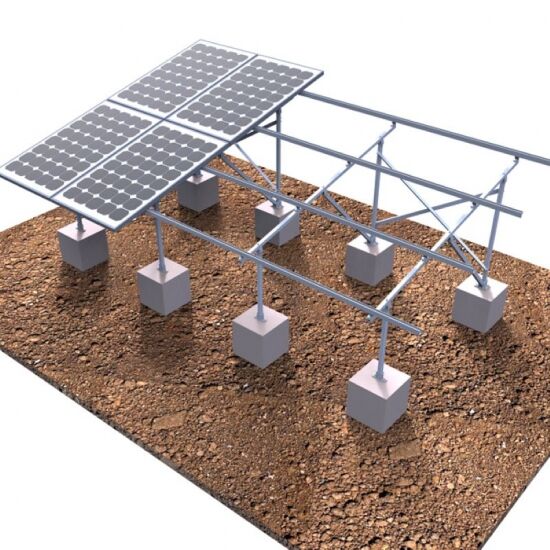

- Frame assembly: Quick assembly of rails and supports using modular components.

- Ballast placement: Strategic placement of concrete blocks to ensure stable fixation.

- Module installation: Securing PV modules with clamps, completing electrical connections.

- System testing: Inspection of structural stability and electrical performance.

Flat Roof Mounting System

SunRack Solar Flat Roof Racking System Technology adopts with a simple and dignified appearance, exquisite and stable structure, on-site installation without welding can be achieved, and with high reliability; to meet the structural carrying capacity features combined with practical, optimize the use of materials. Part of the battery plate connection with the use of rail mounting, suitable for all kinds of solar panels, and convenience for installation; greatly increased the efficiency of field construction, and save cost.

Core Features & Benefits

1. Roof-Friendly Non-Penetrating Design

2. Superior Structural Stability

3. Flexible & Efficient Installation

4. Universal Compatibility & Versatility

5. Cost-Effective Long-Term Operation

Installation & Maintenance

Installation Process

Maintenance Guidelines

Project Reference

FAQ

Q1: Will the mounting system cause roof leakage?

Q2: Can the system adapt to high-wind or heavy-snow areas?

Q3: Is customized design available for special roof conditions?