High Efficiency Flexible Solar Panel Kit Photovoltaic Module Use for Solar Energy System

Installation site: TPO membrane roof

Application: Framed solar panel for any size

Structural materials: aluminum, stainless steel

Survival wind speed: up to 60m / s

Design snow pressure: up to 1.4KN / m2

Inclination: 0 degree (the same angle as roof)

Panel direction: vertical or landscape

Design Standards: BS EN 1991-1-4:2005

/ ASCE7 / DPT1311-501

- Overview

- Recommended Products

- Location: Spain

- Project Scale:2MW TPO waterproof flexible roof solar Mounting System

- Application: Commercial Usage

- Non-penetrating installation, 100% TPO roof protection

- 0°–15° slope adjustable, fits all low-slope roofs

- High efficiency: 15–20 panels installed per day by 2 workers

SFS-PR-01 Sunrack TPO waterproof flexible roof solar Mounting System

1.Product Value Proposition:

2).Cleaning the holes and washing the surface.

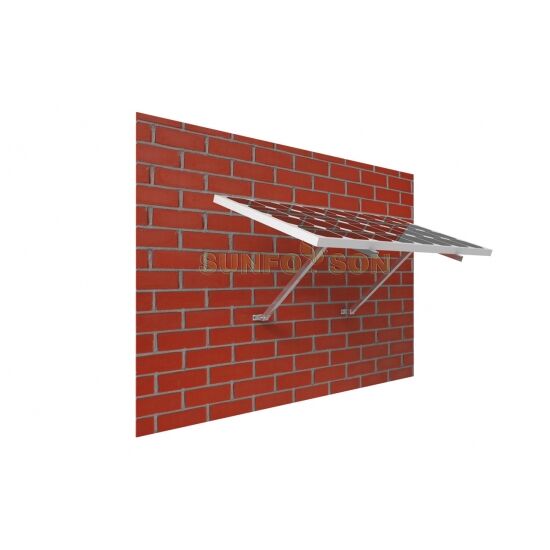

3).Installing the supports.

4).Performing hot air welding.

5).Installing the guide rails.

3.Product Description:

Installation site |

Color steel tile roof or concrete roof |

Panel direction |

vertical or landscape |

Panel Demension |

Framed solar panel for any size |

Inclination |

0 degree (the same angle as roof) |

Wind load |

60m/s |

Material |

Aluminum, stainless steel |

Snow load |

1.4kN/m2 |

Design Standards |

EN1991 |

TPO waterproof membrane is thermoplastic polyolefin waterproof membrane. It is a new type of waterproof membrane made of thermoplastic polyolefin (TPO) synthetic resin that combines ethylene propylene rubber and polypropylene using advanced polymerization technology, with antioxidants, anti-aging agents and softeners added. Polyester fiber mesh cloth can be used as internal reinforcement material to make enhanced waterproof membrane. It belongs to the synthetic polymer waterproof membrane type waterproof product.

-Mark positions (1200mm longitudinal × 1000mm transverse spacing);-Weld pad edges to TPO membrane (300–350℃, 10–15cm/min speed);

2),Rail Installation

-Cut rails to length, deburr; fix on brackets, tighten to 20 N·m

-Rail flatness deviation ≤2mm/m

3),Panel Mounting

Lift panels with suction cups; place on rails with 5–10mm gaps

Install end/mid clamps, tighten to 10 N·m (avoid over-tightening panel frames)

4),Final Inspection

Check component tightness, panel alignment

Water spray test on welds; no seepage allowed

-Use original spare parts for replacement; protect TPO membrane during operation.

-No construction in bad weather; use insulated tools near electrical parts

-Do not drill TPO membrane; total load shall not exceed roof limit

-Avoid heavy pressure on aluminum rails; stack panels flat on pallets

A: Yes. It is suitable for flat or low-slope roofs (≤15°) and can be fine-tuned via adjustment brackets to match roof angles.

Q: Will the installation damage the TPO roof waterproof layer?

A: No. The system adopts a non-penetrating design; base pads are fixed by hot-air welding with TPO membrane, ensuring no damage to the waterproof structure.

Q: What solar panel sizes are compatible with the system?

A: It fits mainstream panel series: Any Size (both framed and frameless).

Q: What is the warranty period of the mounting system?

A: 10-year warranty for system components, excluding damage caused by improper installation, man-made factors or extreme weather beyond design standards.

Q: Can the system withstand strong winds?

A: Yes. It complies with AS/NZS 1170 wind load standards. Adjust base pad spacing according to local wind load requirements for optimal stability.

Q: What tools are essential for routine maintenance?

A: Torque wrench, soft cleaning cloth, hot-air welder (for weld repair) and anti-scratch pads (to protect TPO membrane during operation).