SFS-GM-03 Galvanized Solar Ground Mounting System

1.Product Value Proposition:

Our galvanized steel ground mounting structures SFS-GM-03 are not just simple support structures, but crucial infrastructure for the long-term stable operation of your photovoltaic power plant and for maximizing your return on investment. We are committed to providing cost-effective, highly reliable, and easy-to-install standardized industrial-grade solutions, aiming to reduce our customers' system construction and total life cycle maintenance costs.

2.Features:

1)Superior Corrosion Resistance and Long Lifespan

Utilizing hot-dip galvanizing technology (zinc layer thickness ≥80μm), the steel surface is fully covered, providing excellent cathodic protection and effectively resisting corrosion from rain, salt spray, and soil, ensuring a service life of over 25 years.

2)High Structural Strength and Stability

Made of high-strength steel and optimized through rigorous structural mechanics calculations and simulations, it can withstand extreme wind loads (e.g., ≥150km/h), snow loads (e.g., ≥1.4kN/m²), and seismic loads, guaranteeing system safety.

3)Flexible Adaptability and Strong Compatibility

Modular design with adjustable column spacing and tilt angle, perfectly compatible with mainstream photovoltaic module size requirements.

4)Convenient Installation and Time-Saving

Featuring pre-drilled holes and standardized connectors, most components can be quickly assembled on-site without special tools or extensive welding, significantly reducing installation difficulty and labor costs.

5)Environmentally Friendly and Low Life Cycle Cost

The galvanizing process is environmentally friendly and durable, requiring minimal maintenance. Excellent durability means lower replacement risks and long-term maintenance costs, resulting in a higher return on investment.

3.Product Description:

Item |

Specification |

Material |

Galvanized steel+Aluminum alloy+Stainless steel |

Dimensions |

Customized production based on the customer's site dimensions and solar panel dimensions. |

Survival wind speed |

Up to 130mph (60m/s) |

Survival snow pressure |

Up to 30psf (1.4kN/m2) |

Certification Standards |

CE, ISO 14001, ISO 9001 |

Design Standards |

BS 6399-2-1997&AS / NZS 1170 |

4. Application Scenarios

1)Large-scale Ground-mounted Photovoltaic Power Plants

Product Compatibility & Advantages:

Key Benefit:Suitable for flat or gently sloping terrain, with large-scale array layouts, making them the preferred choice for centralized power generation projects.

2)Commercial and Industrial Distributed Power Plants

Product Compatibility & Advantages:

Key Benefit:Applied to unused rooftops or open spaces in factory parks, logistics centers, and commercial complexes, providing green electricity to commercial and industrial users.

3)Off-grid/Microgrid Systems for Remote Areas

Product Compatibility & Advantages:

Key Benefit:Providing stable and reliable basic support structures for communication base stations, border guard posts, and villages without electricity.

5. Installation&Maintenance Guide

Part 1: Installation Guide

Preliminary Preparations:

Site Survey: Confirm geological conditions (recommended bearing capacity ≥ 80kPa) and level the site.

Material Inventory: Verify all components (columns, diagonal beams, rails, connectors, fasteners, etc.) against the drawings.

Tool Preparation: Spirit level, torque wrench, pile driver/drilling machine, standard wrench set, safety equipment.

Installation Process:

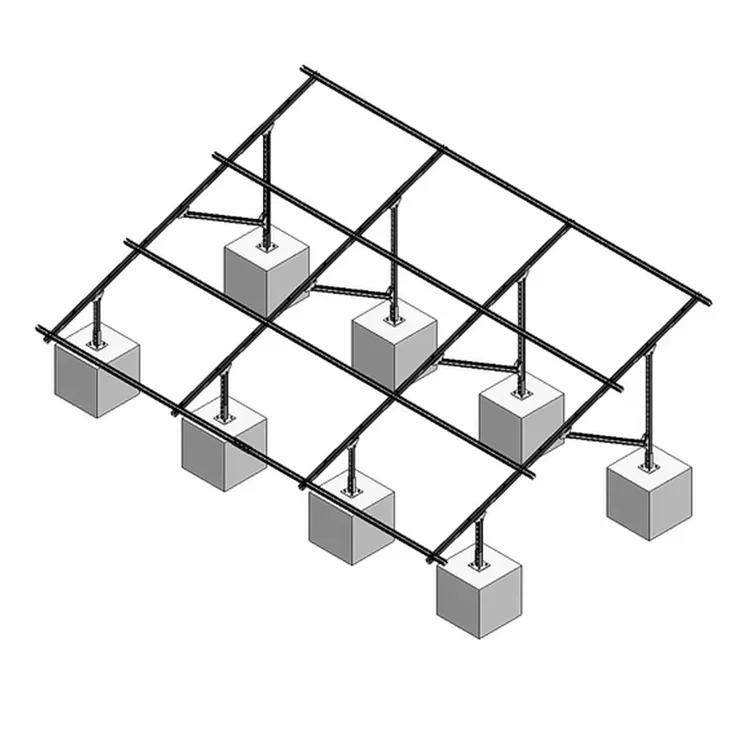

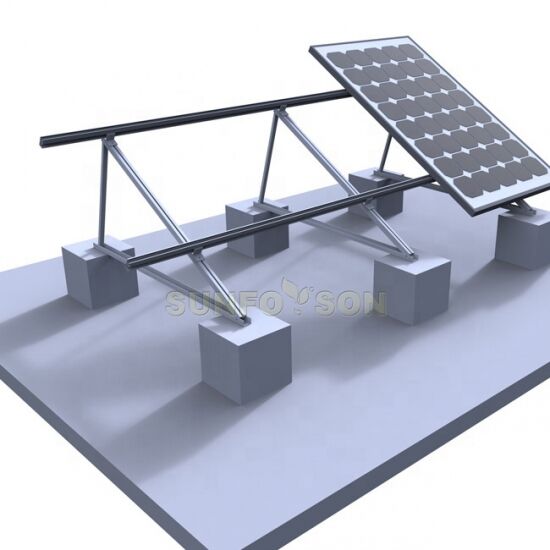

Step 1: Foundation Construction. Position and mark the foundation according to the design drawings, using helical piles, concrete foundations, or ballast blocks to secure the base.

Step 2: Column Installation. Securely connect the galvanized columns to the foundation, and use a spirit level to ensure all column tops are on the same horizontal plane.

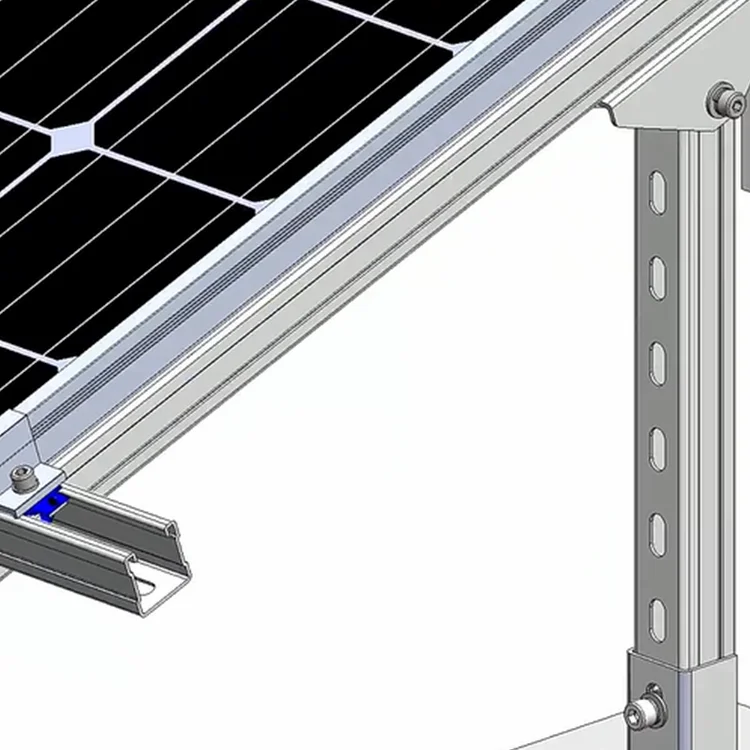

Step 3: Main Beam/Diagonal Beam Installation. Connect the diagonal beams to the columns using bolts, forming a stable triangular support structure.

Step 4: Rail Installation. Fix the rails to the diagonal beams, paying attention to spacing and straightness to ensure smooth component installation.

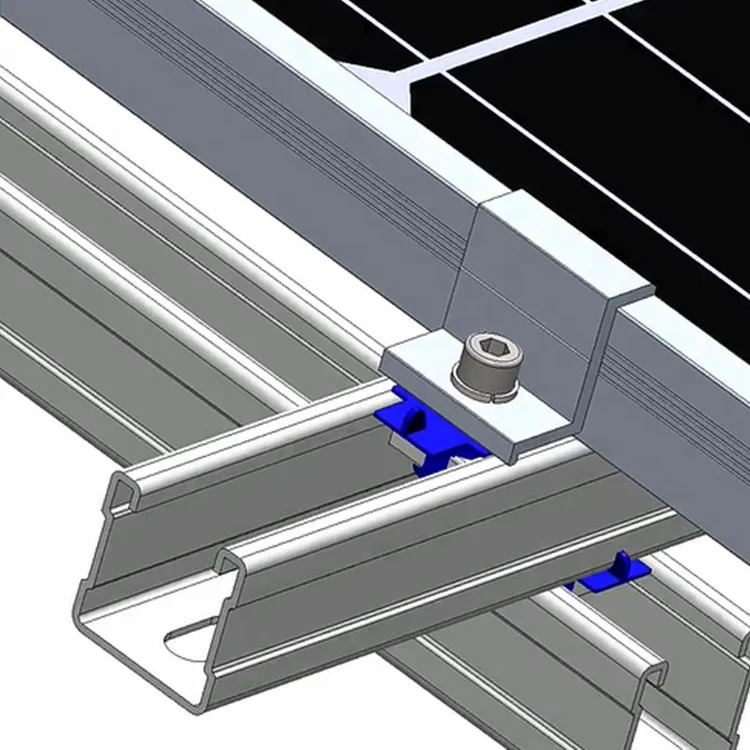

Step 5: Component Installation. Fix the photovoltaic modules to the rails using aluminum alloy clamps, completing the entire array according to the design drawings.

Step 6: Electrical Connection and Grounding. Complete the series and parallel connections of the modules and ensure reliable grounding of the entire support system.

Safety Precautions: High-altitude work and electrical work safety regulations must be followed during installation. Construction is prohibited in adverse weather conditions.

Part Two: Daily Inspection and Maintenance

Regular Inspection (recommended 1-2 times per year):

Structural Inspection: Check all bolt connections for looseness. If loose, retighten to the specified torque using a torque wrench.

Corrosion Inspection: Check the galvanized layer for abnormal scratches or white rust. Small areas of damage can be repaired with zinc-rich paint.

Foundation Inspection: Check the foundation for stability, settlement, or soil erosion.

Post-Disaster Inspection: After experiencing strong winds, heavy rain, heavy snow, or other extreme weather conditions, a comprehensive inspection of the support system should be carried out immediately.

Cleaning: Regular rainwater rinsing is sufficient. When cleaning the modules, avoid strong impacts on the support structure or the use of corrosive cleaning agents.

6. FAQ – Frequently Asked Questions

Q1: What is the difference between hot-dip galvanizing and ordinary spray painting (or cold galvanizing)?

A: Hot-dip galvanizing involves immersing steel components in molten zinc, forming a metallurgically bonded iron-zinc alloy layer. Its rust-proof lifespan is 5-10 times longer than ordinary spray painting and it has a self-healing (sacrificial anode) function. It is the preferred anti-corrosion process for heavy-duty outdoor structures.

Q2: How much wind and snow load can your brackets withstand?

A: Our standard design can withstand Category 13 winds (150 km/h) and a snow load of 1.4 kN/m². The design load for specific projects will be calculated and customized based on meteorological data and local regulations of the project location to ensure safety.

Q3: Does installation require welding?

A: No. We use a fully bolted connection design. All components are pre-fabricated and pre-drilled at the factory, requiring only standard tools for on-site assembly, greatly improving installation efficiency and consistency.

Q4: Are there high requirements for ground flatness?

A: A certain degree of flatness is required. We recommend site leveling before installation. For sloping or uneven ground, adjustments can be made by adjusting the column height or using adjustable pile heads, but this needs to be considered in the design phase.

Q5: What is the minimum order quantity? What is the delivery time?

A: We support project customization, usually calculated in megawatts (MW) or tonnage. The delivery time for standard products is approximately 15-30 days after the contract takes effect, depending on the order size and degree of customization.

7. Customer Cases

Case 1: Galvanized Solar Ground Mounting System – Uganda

- Location: Uganda

- Project Scale:550KW Cement Block Foundation Ground Mount

- Application: Commercial Usage

Performance & Results:

The project has been operating stably for 5 years, having withstood multiple sandstorms and blizzards. The support structures show no structural deformation or serious corrosion, and maintenance and inspection costs are very low. The client is highly satisfied.

Case 2: Galvanized Solar Ground Mounting System – Côte d'Ivoire

- Location: Côte d'Ivoire

- Project Scale: 4MW Ground Mount System

- Application:National Grid power generation requirements

Performance & Results:

The stability of the mounting structure ensured the optimal tilt angle of the components, and the actual annual power generation reached the expected level in the feasibility study, with equivalent utilization hours exceeding 1500 hours. Thanks to the long-lasting corrosion protection of the galvanized coating and the stability of the helical piles, the mounting structure has not incurred any unplanned maintenance costs to date, achieving the "zero maintenance" design goal.